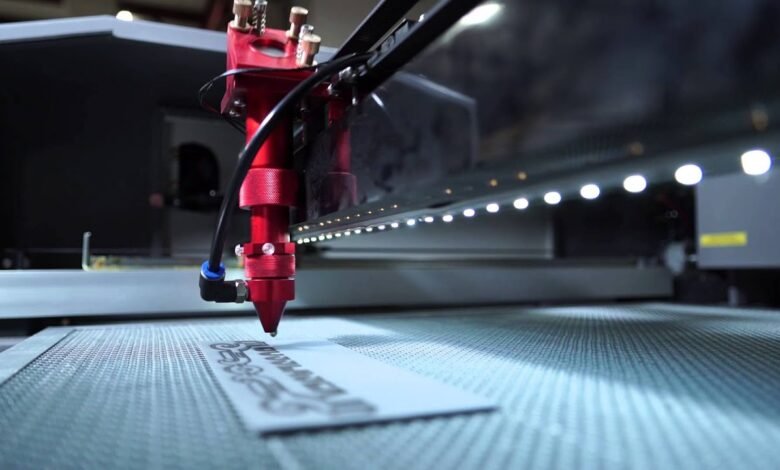

How to Choose the Best Laser Engraving for Your Application

Today there are many different types of lasers where all materials can be marked. There were limitations to the consistency and spectrum of significant materials until a few years ago, but that is not the case any longer.

Based on the material type and predicted outcome, you will find the right Laserowe znakowanie metali. Given the vast array of possibilities to choose an appropriate laser, it is not easy for many operators in the industry to select a laser. We will try in this article to explain what to consider when selecting the right laser marker to fit our needs.

Related: SaaS Tech: Transform the Legacy Industries into Digital Age

First of all the laser features and material properties of our elements have to be understood. When selecting the material, its form, marking quality, its aesthetic, and its pace are the principal parameters to be considered. For stand-alone laser markers, cycle time is used to determine speed. It takes time to complete the complete path of a part, from its device introduction to (if any) reading of 2D code. Cycle time is the time.

You’ve heard of Fiber, Wave, UV and, obviously, CO2 lasers, most of these lasers. Each of these fits in more than one material. In general, we know the laser Fiber because of its full metal performance. For plastics, like the most well known UV laser, the Green Wave Laser is best suited. The CO2 laser for organic material labeling is the most commonly used laser. Technological alternative solutions for specific applications are also available in the Fiber group.

Laser Technologies

The Nd: YAG laser was launched nearly 30 years ago and is perhaps the industry’s best-known. Due to the many uses that it protects. The lasers were originally pumped with lamps. Later they developed and diodes replaced lamps. Diode-based systems have an outstanding life expectancy and are stable. Nd’s benefit: YAG lasers are of the consistency of their laser beams. This is because of the scale of the position. This produces high peak power along with short pulses which can be useful in profound gravure with sharp, simple marks and small characteristics.

Applications of Laser Engraving Technology

In laser marking, the most common words include graving, cleaning, selective removal and removal. Depending on the application and content, one form of laser is better than another. For instance, a vanadate laser works well when we look at the Day&Night components. The surface removal method is suited to the short pulse and repetition speed characteristics of this laser. Speed is essential to prevent plastic components from being burned.

Ablation also is a common practice in laser marking anodized aluminum.

Related: 10 Biz-Tech Ideas for Geeks

The ringing of medical components is another very popular application with a special Fiber Laser. Typically, they’re made of inox and titanium. We are talking about all materials, including prostheses, surgical instruments and dental components, of course. The Picosecond laser’s high peak power is perfect for achieving black and unmalpable markings here.

The resistance to passivation cycles and corrosion from this laser marker is greater than in other cases by aggressive agents. This is because laser marking can be used to indicate essential dimensional data about the component in question for the surgeon. Another factor that advantages this product over other medical products is the poor reflective effect of the Picosecond laser.

Choosing a laser marker

In future years the field of lasers and labeling will keep growing and evolving. The technology must meet the changing requirements of the production environment and the competitive market. The choice of a laser marking provider is very important as a broad range of products is provided and errors can be made easily. Confident on someone who knows her work means also taking advantage of the advice of a professional who knows how and not the reverse to adapt her bid to our needs.